European Standards for Gloves

Gloves are certified compliant with the texts and tests defining the standards indicated for each model as per guidelines.

CE category

Directive 89/686/EEC

![]()

Category I Minor risks

Category II Reversible risks

(injury), certified compliant by a notified body.

Category III Irreversible risks

(corrosion), certified compliant and tested by a notified body whose number is specified.

EN 420 General Requirement

EN 388 Mechanical Protection

| Test | Performance Levels | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| a) | Abrasion resistance (cycle) | >100 | >500 | >2000 | >8000 | - |

| b) | Blade cut resistance (index) | >1.2 | >2.5 | >5 | >10.0 | >20.0 |

| c) | Tear resistance (newton) | >10 | >25 | >50 | >75 | - |

| d) | Puncture resistacne (newton) | >20 | >60 | >100 | >150 | - |

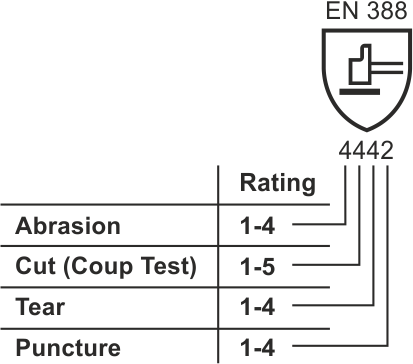

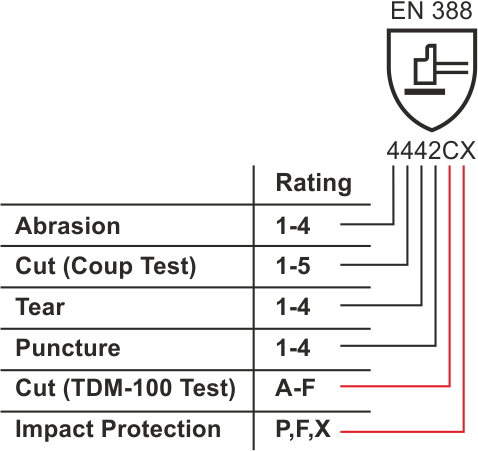

NEW EN 388 Standard & Test Method

Current Marking

New Marking

| EN 374 | Chemical Protection and Micro-organism |

| EN374-1 | (terminology and performance requirement) |

| EN374-2 | (resistance to penetration) |

| EN374-3 | (resistance to permeation by chemicals) |

EN 374-2 Micro-organisms Resistance Glove

| AQL Level | Performance Levels | AQL ≥ 2 | ||

|---|---|---|---|---|

| 4.0 | 1.5 | 0.64 | ||

EN 374-3 Low Risk Chemical Protection Glove

EN 374-3 Low Risk Chemical Protection Glove

Breakthrough times more then 30mins (levels 2) for a minimum of 3 specific chemical listed below and water proof. Therefore the letter code of the chemicals can be more than 3 letters and up to 12.

| Code | Chemical |

|---|---|

| a | Methanol |

| b | Acetone |

| c | Acetonitrile |

| b | Dichloromethane |

| e | Corbon disulpide |

| f | Toluene |

| g | Diethylamine |

| h | Tetrahydrofurane |

| i | Ethyl acetate |

| j | n-Heptate |

| k | Sodium hydroxide 40% |

| l | Sulphuric acid 96% |

EN 511 Cold Protection

| Test | Performance Levels | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| a) Resistance to convective cold | I > 0.1 | 0.1 < I < 0.15 | 0.15 < I < 0.2 | 0.22 < I < 0.3 | 0.3 < i |

| b) Resistance to contact cold | R < 0.025 | 0.025 < R < 0.05 | 0.05 < R < 0.1 | 0.1 < R < 0.15 | 0.15 < R |

| c) Permeability to water | Fail | Pass | |||

(*Fail: water penetrated after 30min; Pass: no water penetrated after 30min)

EN 407 Thermal Risk Protection

| Test | Performance Levels | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| a) Burning behavior | ≤ 20 | ≤ 10 | ≤ 3 | ≤ 2 | |

| after burn (Times sec) | |||||

| after glow (Times sec) | N/R | ≤ 120 | ≤ 25 | ≤ 5 | |

| b) Contact heat (Temp in °C after 15 sec) | 100 | 250 | 350 | 500 | |

| c) Convective heat (heat transfer delay sec) | ≤ 4 | ≤ 7 | ≤ 10 | ≤ 18 | |

| d) Radient heat (heat transfer delay sec) | ≤ 5 | ≤ 30 | ≤ 90 | ≤ 150 | |

| e) Small splashes of molten metal (drop) | ≤ 5 | ≤ 15 | ≤ 25 | ≤ 35 | |

| f) Large splashes of molten metal (g) 30 | 30 | 60 | 120 | 300 | |

EN 60903 Electric Risk Protection

| Class (X) | Tested at Voltage | Approved for work under voltage |

|---|---|---|

| 00 | 2500 | ≥500 |

| 0 | 5000 | ≥ 1000 |

| 1 | 10000 | ≥ 7000 |

| 2 | 20000 | ≥ 17000 |

| 3 | 30000 | ≥ 26500 |

| 4 | 40000 | ≥ 36000 |

| Category (Y) | Addition Requirement |

|---|---|

| A | Acid resistance |

| H | Oil resistance |

| Z | Ozone resistance |

| M | Resistance against high mechanical strain |

| R | Oil, Ozone and high mechanical strain |

| C | Resistance against extreme cold |

EN 12477 Welding Glove